Injection Rubber Stopper Manufacturer – Custom Plastic Injection Molding – Honor Brothers

Injection Rubber Stopper Manufacturer – Custom Plastic Injection Molding – Honor Brothers Detail:

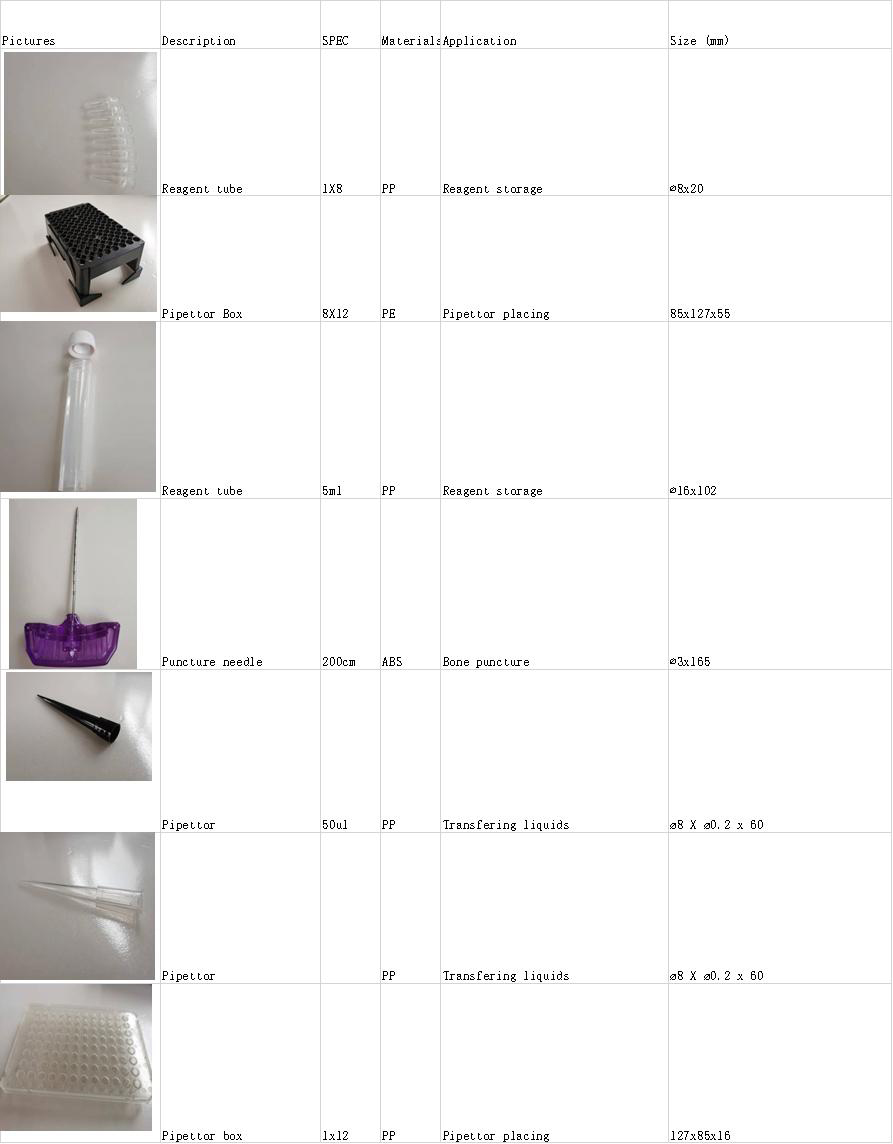

Product Parameters

| Workshop class | |

| Plastic Certification | RoSH, SGS, food grade, Medical grade, UL, UV |

| Mold building time | Mostly 4-5 weeks, can be flexible to meet with your urgent delivery |

| Surface Treatment | Texture, gloss, polishing, silk printing, painting, etc… |

| Production time | After sample is confirmed, 2 weeks for mass production |

| Production duration | 300000 shots to 1,000,000 Shots. |

| Equipment | Injection Molding Machine from 40-650T available. |

About Plastic

|

Name |

Main Feature |

Application |

|

PE |

High pressure polyethylene is soft, transparent and non-toxic. Low pressure polyethylene rigid, wear resistance, corrosion resistance, electrical insulation is better | High pressure polyethylene: film, hose, plastic bottle; Low pressure polyethylene: chemical equipment, pipes, low load bearing gear, bearings, etc |

|

PP |

Strength, hardness and elasticity are higher than polyethylene, low density, good heat resistance, excellent electrical insulation and corrosion resistance, poor toughness, no wear resistance, easy aging | Flange, gear, fan impeller, pump impeller, handle, TV (radio recorder) shell and chemical pipes, containers, medical instruments and so on |

|

PVC |

Higher strength and better corrosion resistance. Soft polyvinyl chloride, with high elongation, soft products, good corrosion resistance and electrical insulation | Exhaust gas detoxification tower, gas liquid conveying pipe, centrifugal pump, fan, joint; Soft PVC: film, raincoat, acid and alkali resistant hose, cable sheath, insulation layer, etc |

|

PS |

Good corrosion resistance, electrical insulation, transparency, strength, stiffness, heat resistance, wear resistance is not high, poor impact resistance, flammable, easy to crack | Bobbin, yarn, spool; Instrument parts, equipment shell; Storage tank, pipe, elbow; Lampshades, transparent Windows; Electrical insulation materials, etc |

|

ABS |

High strength and impact toughness, good wear resistance and heat resistance, high chemical stability and insulation, easy to form, good machinability, poor resistance to high and low temperature, inflammable, opaque | Gear, bearing, instrument panel shell, refrigerator lining and all kinds of containers, pipes, aircraft cabin decoration board, window frame, sound insulation board, also can make car body and fender, handrail, hot air regulating duct and other auto parts |

|

PA |

Good strength, hardness, wear resistance, corrosion resistance, vibration absorption, self-lubrication, formability, non-toxic, tasteless. Creep value is large, poor thermal conductivity, high water absorption, forming shrinkage | Nylon 610, 66, 6, etc., manufacturing small parts (gear, worm gear, etc.); Aromatic nylon for high temperature wear resistant parts, insulation materials and cosmological clothing. It should be noted that the properties and dimensions of nylon change greatly after water absorption |

|

PC |

High tensile and flexural strength, good impact toughness and creep resistance, high heat resistance, cold resistance and dimensional stability, high transparency, small water absorption, good insulation and processing formability, poor chemical stability | Gaskets, gaskets, bushing, capacitors and other insulating parts; Instrument housing and cover; Manufacture signal lights, windshields, cockpit hoods, helmets, etc., in aviation and aerospace industries |

|

PTFE |

Excellent chemical corrosion resistance, excellent high and low temperature resistance, small friction coefficient, small water absorption, low hardness, strength, tensile strength is not high, high cost | Antifriction seals, chemical corrosion resistant parts and heat exchanger heart and insulation materials under high frequency or humid conditions, such as chemical pipelines, electrical equipment, corrosive media filters, etc |

|

PMMA |

Transmittance 92%, relative density is half of glass, high strength, toughness, uv resistance, anti-aging atmosphere, easy to form, hardness is not high, not wear-resistant, soluble in organic solvents, heat resistance, poor thermal conductivity, large expansion coefficient | Aircraft cabin cover, turret viewing hole cover, instrument lamp shade and optical lens, bulletproof glass, TV and radar plotting screen, automobile windshield, instrument and equipment protective cover, etc |

|

PE |

Certain strength and hardness, high wear resistance, heat resistance, good insulation and corrosion resistance, stiffness, low moisture absorption, small deformation, simple forming process, low price. Disadvantage is brittle quality, not alkali resistance | Plug, switch, telephone, instrument box, brake pad of automobile, crankshaft of internal combustion engine, belt wheel, silent gear of textile machine and instrument, acid-proof pump for chemical industry, daily appliance, etc |

|

EP |

High specific strength, good toughness, heat resistance, cold resistance, corrosion resistance, insulation, waterproof, moisture-proof, mildew resistance, good forming process and dimensional stability. Toxic, expensive | Plastic moulds, precision measuring tools, potting appliances, aircraft paint, tanker paint, can paint, printing lines, etc |

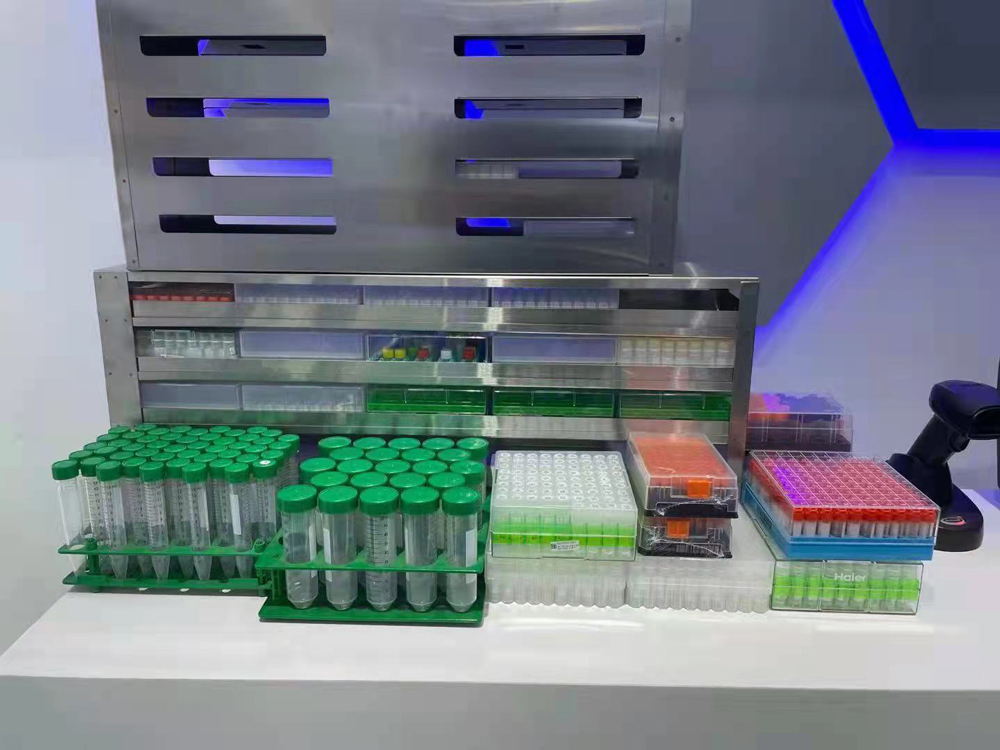

Application

Widely use to medical equipment industry , automobile parts ,fitness field, toy, gift, production field, electronic field, industrial machine & equipment, agricultural machine & equipment, house-hold appliance, tele-communication .

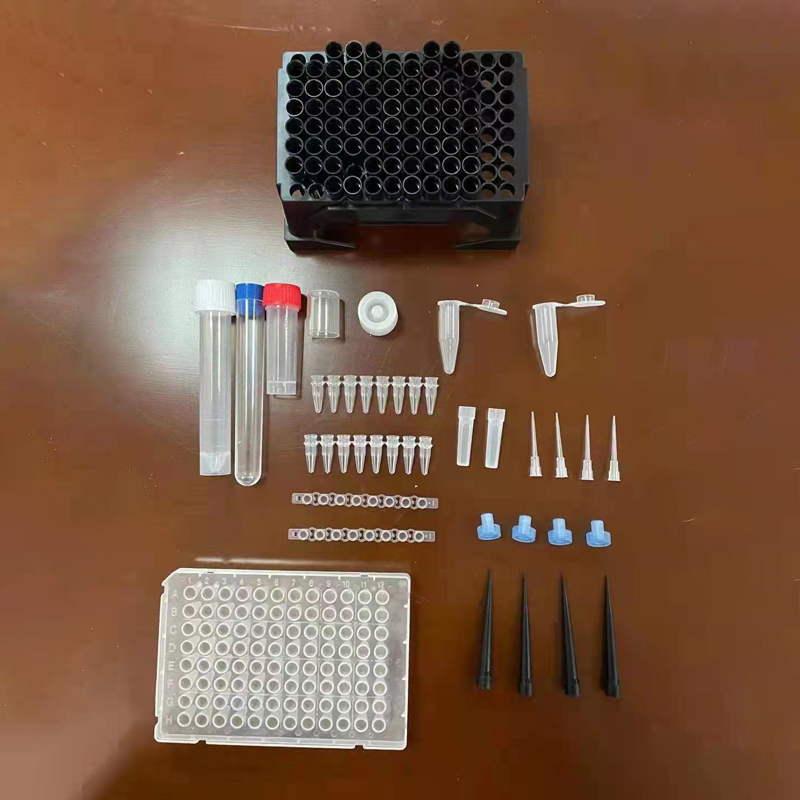

Product View

Packaging&Shipping

Product detail pictures:

Related Product Guide:

All we do is usually connected with our tenet " Consumer initial, Rely on 1st, devoting around the food stuff packaging and environmental safety for Injection Rubber Stopper Manufacturer – Custom Plastic Injection Molding – Honor Brothers , The product will supply to all over the world, such as: California, Palestine, Toronto, If you give us a list of products you are interested in, along with makes and models, we can send you quotations. Please email us directly. Our goal is to establish long-term and mutually profitable business relationships with domestic and overseas clients. We look forward to receiving your reply soon.

This is a very professional wholesaler, we always come to their company for procurement, good quality and cheap.